There are several different definitions of Digital Twins or Clones and many use them interchangeably with terms such as Industry 4.0 or the Industrial Internet of Things (IIOT). Fundamentally Digital Twins are digital representations of a physical asset, process or product and behave similarly to the object it represents. The concept of Digital Clones has been around for a while and earlier models were based on engineering principles and approximations. This required a very deep domain expertise, was time consuming and limited to a few use cases.

Today Digital Clones are virtual models that are built entirely by using massive historical datasets and Machine Learning (ML) to extract the underlying dynamics. The data driven approach makes Digital Clones accessible for a wide range of applications. As a consequence, the potential for Digital Twins is enormous and includes process enhancementsoptimization, equipment life cycle management, energy reductions, safety improvements just to name a few.

Building digital clones require:

1. A large historical data set or data historian.

2. High data quality and sufficient data granularity.

3. Very fast data access.

4. A large GPU for the model development and real time predictions.

5. A supporting data structure to manage the development, deployment, and maintenance of ML models.

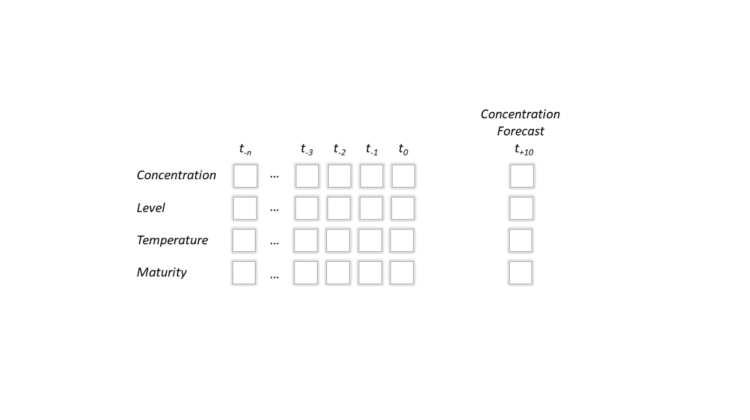

The following shows the application of a Digital Twin to a batch process example. The model is built using 30 second interpolated data using a window of past data to predict future (5 min) data points:

The power of Digital Clones is that they are not only able to predict process conditions but also provide explanatory power on what drives the process — the underlying dynamics. The following dashboard shows a replay of this analysis including the estimate of the model weights:

The availability of enterprise level data historians and deep learning libraries allow Digital Clones to be implemented on the equipment and process level throughout manufacturing. The technology allows a wide range of applications and offer an insight into the process dynamics that has not been available before.